Garment Sample Development Process

Garment Sample:

Garment samples are inevitably important and are developed tested before starting the bulk production. It means making a sample of the garment or fabric which requires to be sold. Sampling is one of the main processes in Garment Industry and it has a vital role in attracting buyers. Because the buyers generally places the order after they are satisfied with the quality of the samples.

|

| Garment Sample Development Process |

Sample Developing Procedure:

1st sample:

The processes of 1stsample are given in bellow:

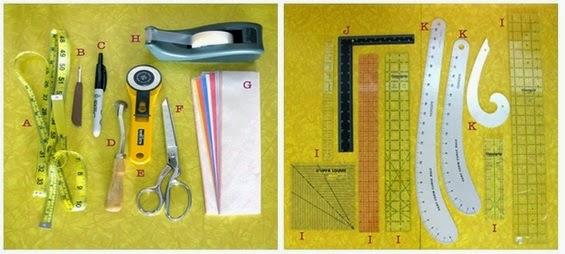

- Receive spec sheet of garments from buyer.

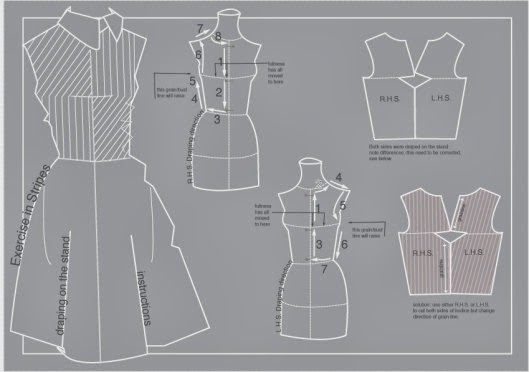

- Make pattern as per measurement.

- Check the pattern which has made.

- If necessary Check shrinkage, twisting, bowing before pattern makingCutting fabric as per pattern.

- Collect accessories.

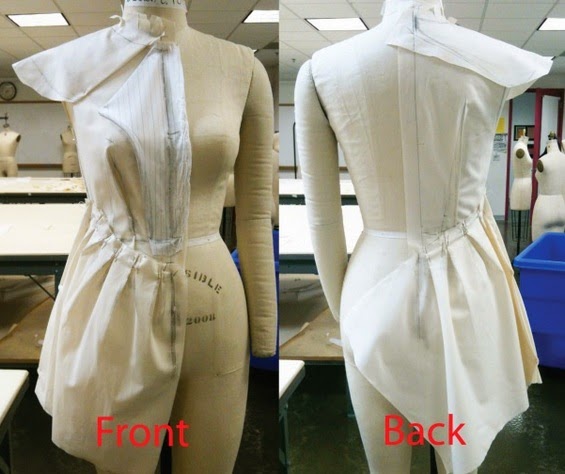

- Start sewing.

- M/C specified.

- Check the sample to ensure it, ok.

- Actual size required.

- Actual fabric construction.

- Send it to buyer for approval.

After approving of 1stsample, the work of development sample is start. The process of Development sample is given in bellow.

- Make pattern as per measurement, if buyer change the measurement to observe the counter sample.

- Actual size required

- Check the pattern which has made.

- Collect actual color fabric. G.S.M should be ok.

- Cutting fabric as per pattern.

- Collect actual accessories.

- Start sewing.

- M/C specified.

- Check the sample to ensure it, ok

- Send it to buyer for approval