This inspection depends on AQL which means Acceptable Quality Level. Please note, during Inspection, defective goods are categorized as Critical, Major or Minor according to their importance to the customers. One critical defect can make us failure in result of Inspection, so, we all need be more sincere about defects.

- Critical Defect is one that relates to a safety or legal problem, or a delivery error which prevents distribution of the product to the customer.

- Major defect is one that significantly affects the usefulness or attractiveness of the product, because it always results in a customer return and / or an immediate or later complaint.

- Minor defect is one which may not always be noticed by the user, and which doesn’t really affect the usefulness or attractiveness of the product.

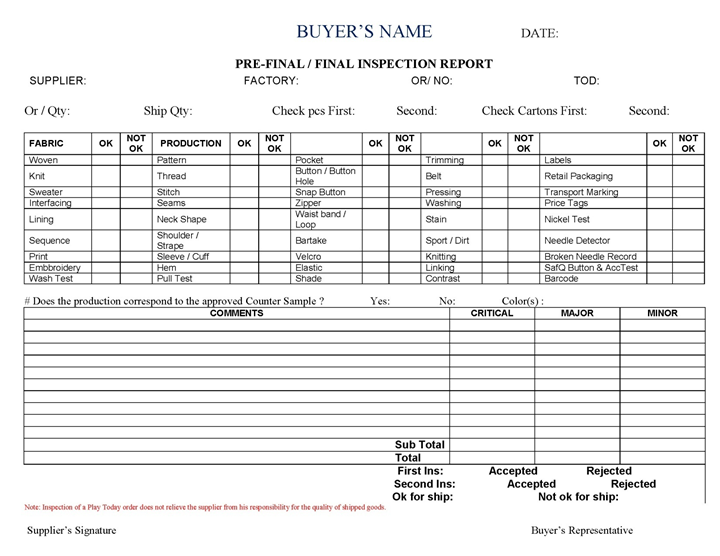

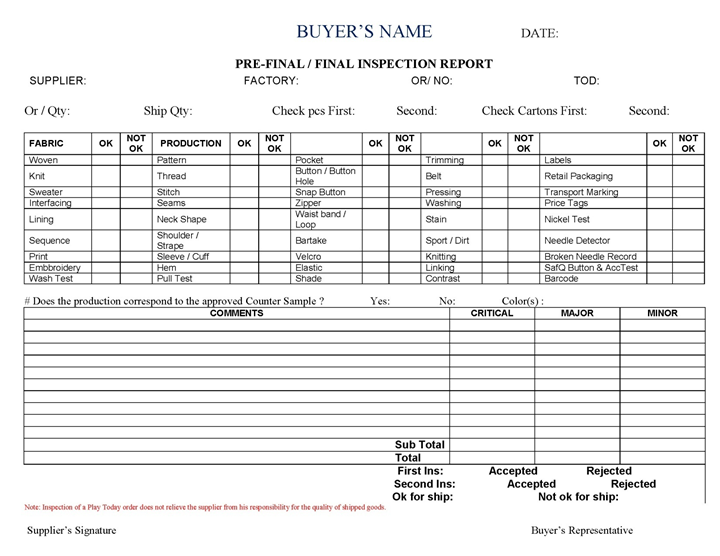

See following image of Final Inspection Sheet.

|

| Click on image for large size |

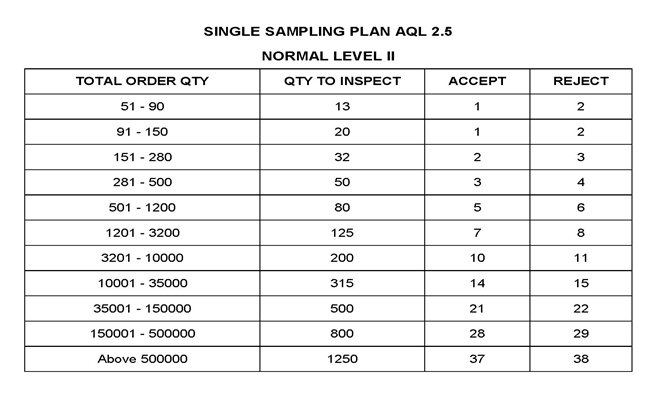

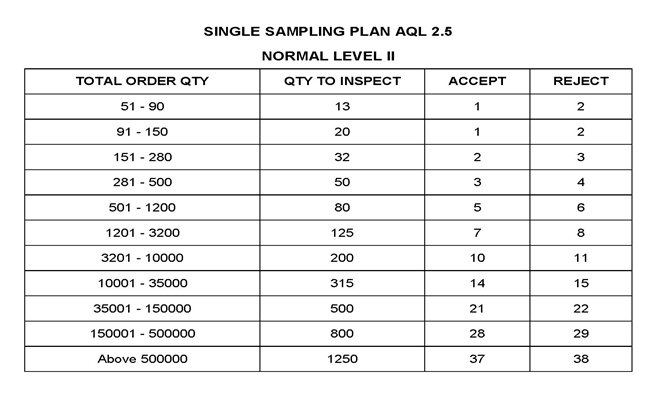

Inspection Sampling Plans: During Final Inspection, we need sampling plans. There are several sampling plans available with 4 features that separate them from others. It’s quite not possible to describe in brief. We need read lots in books regarding Inspection Sampling Plans. These are:

- AQL (1.0, 1.5, 2.5, 4.0, 6.5)

- Type (Normal, Tightened, Reduced)

- Plan (Single, Double)

- Level (I, II, III)

The following Inspection Plan is in the most of Bangladeshi Factories.

- AQL = 2.5

- Type = Normal

- Plan = Single

- Level = II

See image below for your reference.

|

| Click on image for large size |

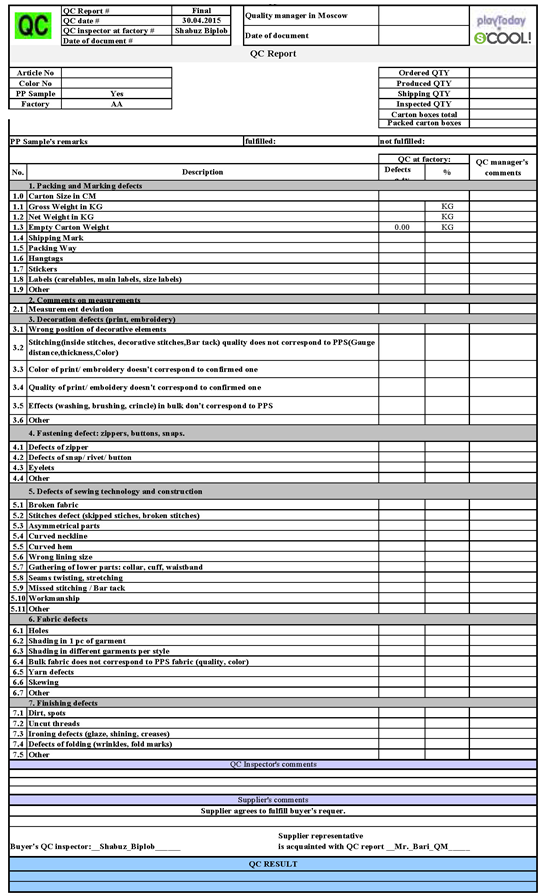

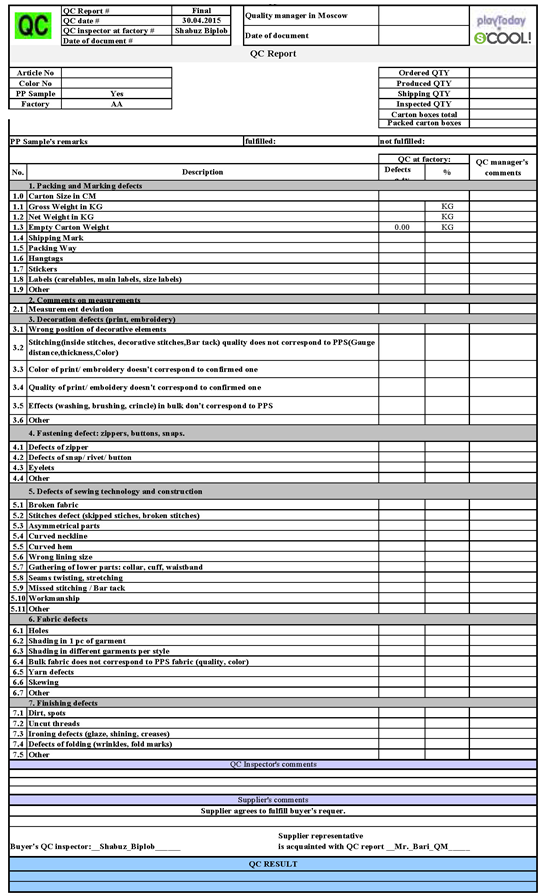

Few buyers don’t follow any AQL for their Inspection System. Instead of AQL, they follow percentage of defective goods in the Order. If any defect of product exceeds 3%, then the goods will be rechecked for those defects. See the sheet in image that few buyers use as Final Inspection Report based on percentage of defects.

|

| Click on image for large size |

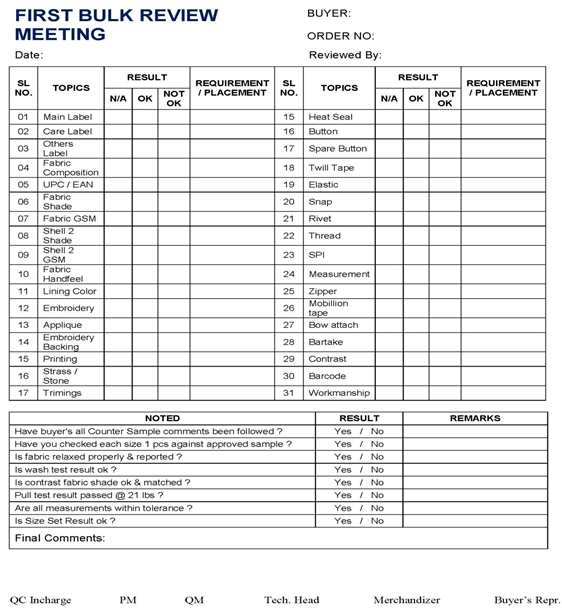

During these inspections, various types of reports & records are seen & followed such as Quality Risk Assessment Report, Fabric Visual Inspection Report (4 Point System), Fabric Wash Test Report, Fabrics GSM, Spirality & Shrinkage Test Report, Fabric Relaxation Report, Lay & Marker Check Report, Cut Panel Measurement Report, Process Control Report (7 pieces), Traffic Light System, Hourly Q. C. Pass Production Report, Hourly Final Inspection Report by factory QC, Inline Inspection Report by factory QC, Pre-final Inspection Report, Pre-production Meeting Record, Loose Metal Control Register, Pull Test Record, Nickel & Ferrous Test Record, Shade-wise Country Plan & Shade Record, Hourly Internal Quality Audit, Corrective & Preventive Plan, Monthly Worker Training Program, Production Reporting & planning, Shipping Documentation etc. So, we can understand how difficult it is to explain in brief. One needs years to learn it. I just picked up a drop of water from sea. I’m learning & I suggest you to learn more & more. I added few Images here for references. If you need these images in other formats, please email me. Thank you.

কোন মন্তব্য নেই:

একটি মন্তব্য পোস্ট করুন